Among these, state of the art stick packing machines for greater efficiency stick served packaging for single-use or portable formats of products has become a cornerstone in packaging. These machines are compact, efficient, and give unique long, skinny packages that everyone calls stick packs. From powdered beverages and condiments to pharmaceuticals and cosmetics, stick packing machines present a different approach to process the various goods. Now, we mainly talk about the essential characteristics, uses, and benefits of stick packing machines, showcasing how they enable efficiency and fulfil changing consumer needs in a dynamic market.

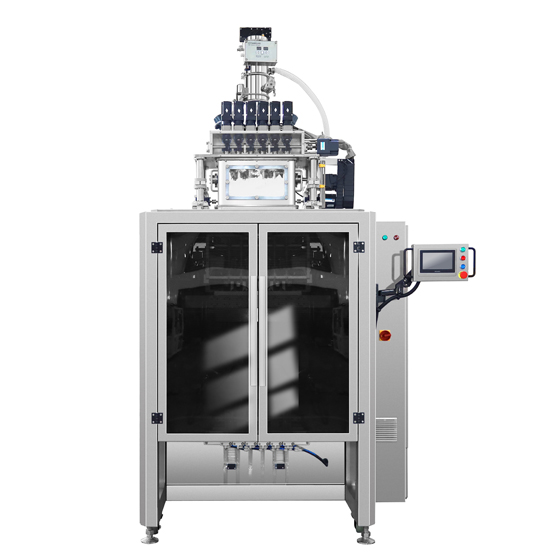

Coretamp stick packing machine is another type of vertical form fill seal (VFFS) equipment meant for producing tightly packed narrow, lengthy pouches. Form, fill, seal single-serve packetsare consistent and fast –these machines create packets from a roll of film.The design is called a stick pack: This is a thin, versatile shape that is both visually pleasing and efficient. Such design is more suited for portable and accurate doses, making it one of the most popular in industries that rely on practicality.

Modern stick packing machines are available in multi-lane systems, which makes it possible to produce multiple stick packs at once. The design makes a big jump in production efficiency, and is particularly needed in high-volume areas such as food and pharmaceuticals.

Advanced filling systems cater to a wide range of product consistencies, from powders and granules to liquids and pastes. Auger fillers, piston fillers, and volumetric fillers ensure accuracy and minimize product waste.

Stick packing machines are designed to occupy minimal floor space, making them ideal for facilities with limited production areas. Despite their small footprint, they deliver impressive speed and versatility.

Equipped with user-friendly PLCs and touchscreen interfaces, stick packing machines allow for seamless operation. Operators can easily adjust parameters, monitor production, and diagnose issues, ensuring smooth performance.

Stick packing machines reduce material waste by optimizing film usage. Their precise filling systems ensure minimal product loss, leading to significant cost savings over time.

Stick packs are lightweight, compact, and easy to carry, making them perfect for on-the-go consumers. Their single-serve format also eliminates the need for measuring, enhancing user convenience.

With proper sealing and barrier materials, stick packs provide excellent protection against environmental factors like moisture, air, and light, preserving product freshness and quality.

Many stick packing machines are compatible with eco-friendly films, allowing businesses to adopt sustainable packaging practices. Additionally, their efficient material usage aligns with waste-reduction goals.

Modern stick packing machines incorporate IoT (Internet of Things) technology, enabling real-time monitoring, data analysis, and predictive maintenance. This reduces downtime and enhances overall productivity.

Advanced sealing systems ensure reliable seals even at high speeds. Innovations like ultrasonic sealing further improve efficiency and reduce energy consumption.

Manufacturers now offer machines that work seamlessly with biodegradable and recyclable films, helping businesses meet environmental regulations and consumer preferences.

Advanced sensors and filling mechanisms ensure accurate dosing for products with varying densities, reducing inconsistencies and maintaining brand trust.

Stick packing machines are a game-changer for businesses seeking efficient, portable, and consumer-friendly packaging solutions. Their versatility, combined with advancements in automation, precision, and sustainability, makes them indispensable in modern manufacturing. By investing in a stick packing machine tailored to your needs, you can enhance operational efficiency, reduce costs, and deliver high-quality products that meet the evolving expectations of consumers worldwide.

Relevant Recommendation