Sachet Filling Machine: Precision Packaging for a Portioned World

In today’s fast-paced consumer market, convenience, hygiene, and precise portioning are paramount. Across industries—from instant coffee and condiments to pharmaceuticals, cosmetics, and chemical additives—the single-serve sachet has become a global standard. This ubiquitous format demands packaging technology that is not only fast and reliable but also exceptionally accurate. The sachet filling machine stands as the engineering hero behind this everyday convenience, and for manufacturers seeking excellence in this critical equipment, Ruipuhua has established itself as a name synonymous with precision, versatility, and enduring performance.

The Critical Role of Precision in Sachet Production

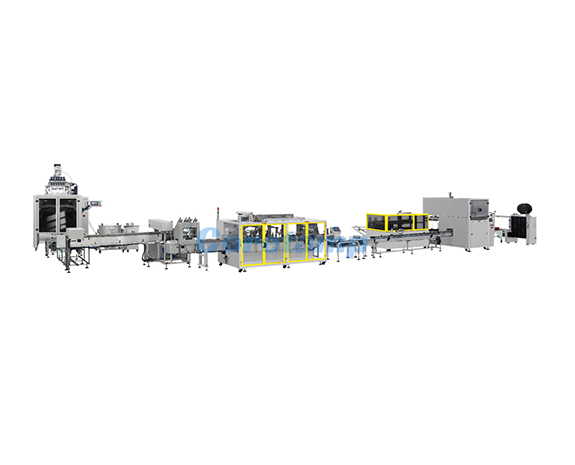

A sachet filling machine does far more than simply put product into a pouch. It is a sophisticated system that orchestrates a multi-stage process with exacting standards: forming the sachet from a roll of film, accurately dosing the product, and creating a secure, hermetic seal—all at high speeds. Even a minor deviation in fill weight or seal integrity can lead to significant product giveaway, consumer dissatisfaction, or compromised shelf life. Ruipuhua engineers its machines with this imperative for precision as the foundational principle, understanding that accuracy directly translates to cost savings and brand protection for their clients.

Ruipuhua’s Engineering Philosophy: Adaptability Meets Robustness

What distinguishes a Ruipuhua sachet filling machine is its core design philosophy, which balances advanced technological capability with practical, durable construction. Recognizing that manufacturers handle an immense variety of products, these machines are built for adaptability.

Intelligent Operation for Modern Manufacturing

A Ruipuhua sachet filling machine is designed for the realities of modern smart factories. Central to its operation is an intuitive touch-screen Human-Machine Interface (HMI) that provides operators with complete control. Production parameters such as fill weight, sealing temperature, and machine speed can be set and adjusted with ease. The system allows for storage of numerous product recipes, enabling rapid changeovers between different sachet sizes or products with minimal downtime—a key feature for batch production.

Beyond control, these machines offer insight. Integrated monitoring systems can track production counts, efficiency, and alert operators to potential issues like film jams or low product supply. This connectivity and data provision support lean manufacturing principles and overall equipment effectiveness (OEE) initiatives, transforming the machine from a standalone tool into a connected asset within the production line.

Built for Durability in Demanding Environments

Packaging halls are demanding environments, and Ruipuhua builds its sachet filling machines to endure. The primary structure and product-contact parts are constructed from high-grade stainless steel, ensuring corrosion resistance, compliance with hygienic standards (particularly vital for food and pharmaceutical applications), and long-term structural integrity. The drive systems and mechanical components are selected for reliability, ensuring consistent operation across multiple shifts and reducing the total cost of ownership through minimized maintenance and downtime.

Driving Value Across Key Sectors

The application of Ruipuhua’s sachet packing technology is vast and varied:

A Partnership for Packaging Success

Choosing a sachet filling machine is a significant investment in a brand’s packaging future. Ruipuhua supports this partnership from the initial consultation—where product characteristics and output goals are analyzed—through comprehensive factory testing, installation, operator training, and responsive after-sales support. This end-to-end commitment ensures that each machine delivers on its promise of performance from day one and continues to do so for years.

For brands looking to capitalize on the growing demand for portioned, convenient, and hygienic packaging, the precision-engineered sachet filling technology from Ruipuhua offers a proven pathway. It represents a fusion of mechanical reliability and intelligent control, designed to protect your product, optimize your costs, and uphold your brand reputation with every perfect sachet it produces.

To explore the detailed specifications and discover how a Ruipuhua sachet filling machine can be configured for your specific product and production goals, visit www.coretampmachinery.com. Learn how our engineering expertise can become the reliable core of your single-serve packaging line.

Relevant Recommendation