One of the paramount machines that are prominent in today’s packaging sector is the powder packaging machine. This machine is designed to dispense the various products in powdered states effectively and accurately.

Among the most important needs of any product is its packaging, whether foods, pharmaceuticals, or chemicals, as the packaging will maintain the value of the product and greatly extend the shelf life of the product. This article will talk about powder packaging machine types, features, and the benefits that they are offering.

A powder packaging machine is nothing but a highly technical machine meant for productively handling the powder for packaging. They are applied in almost all industries so that the products are packed in a way that does not allow the quality of the products to diminish and that they are stored for a longer duration.

Powder packaging machines can pack products into bags, bottles, pouches, and containers in order to keep the powder from getting damp, contaminated, or partially making it unsuitable for handling during storage and transit.

The evolution of powder packaging machines dates back several decades. Packaging was done through manual handling during the initial periods. The manual handling, besides being waste of labor, was something susceptible to errors. Technological advancement then contributed to the advent of semi-automatic and fully automatic machines with better efficiency and accuracy in packaging; the early machines were simple in design and only focused on the basic task of filling powders into containers.

However, as time elapsed, there arose a rise in the due demand for manufactured products as well, and the demand for advanced machinery rose. The modern powder packaging machines are very much advanced in technology. They have digital controls, features to maintain filling precision, and features to adapt different types of packing materials.

The manual powder packaging machines require human involvement in almost the entire packaging process. They are suitable for small-sized operations and packaging where the volume of powder being packaged is not very high. They are cost-effective machines and easy to use but not applicable in large-volume production setups because they can be labor-intensive. Generally, they include basic features like a hopper for holding the powder, a hand-operated lever for dispensing, and simple sealing mechanisms.

These are middle of the way between manual and automatic machines. Some tasks are still human directed, while others are automated. These machines are thus good for medium scale operations. They strike the right balance to be economically viable as well as productive at the same time. Most often, they have filling mechanisms automated, but the packaging and sealing are still directed by human hands.

Fully automatic powder packaging machines go through the whole process without any human intervention. These machines are, in fact, the right option for high production lines where both speed and precision are needed. These machines are incorporated with features such as programmable logic controllers, touch-screen interfaces, and automatic filling, sealing, and labeling operations. They are continuously working and assure packaged quality by reducing human error. Fully automatic machines are ideal for high-production industries such as food processing, pharmaceuticals, and chemicals.

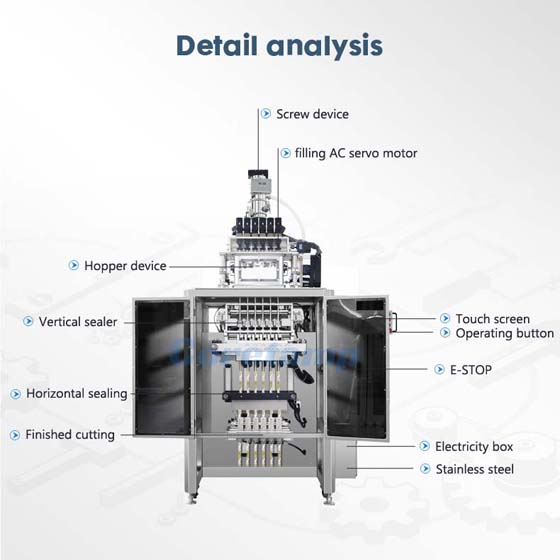

The powder packaging machines mainly consist of the following parts:

Hoppers: Store the powder until it is released into the packaging.

Filling Systems: The filling system correctly measures the specified amount of powder in each package.

Sealing Systems: The packages are properly sealed to avoid any kind of pollution and spillage.

Control Panels: Allow operators to view and regulate the machine settings.

Conveyors: They assist in conveying packages between various stages in the process of packaging.

Modern powder packaging machines come with advanced features such as:

Touch Screen Interface: It has an interface in which an operator will be able to control and monitor the operations.

Programmable Logic Controllers (PLCs): Automates complex processes in the packaging process and can be used to link other systems in the production process.

Automatic Weight Adjustments: Ensures the precise amount of powder is included in each package.

Quick Changeover Systems: For high versatility in format changes.

Integrated Quality Control: Metal detectors and check weighs, ensure product quality and safety.

Powder packaging machines are used within the food industry for the reservoir of flour, spices, protein, cocoa, and baking mixes. With this kind of machinery, packaging is achieved properly and accurately, hence leading to maintaining the freshness of the products, not contaminating them. The packaging also plays a crucial role in branding and marketing, making the product appealing to consumers.

Powder packaging machines are used in the industry of pharmaceuticals to pack powdered drugs and medications that contain antibiotics, dietary supplements, and nutritional supplements. In this industry, precision is critical to ensure the correct dosage. These machines must meet strict regulatory standards to ensure the safety and effectiveness of the packaged product.

The machines are used to package detergents, fertilizers and industrial chemicals. The exact measurement of packaging is what will allow safety against hazardous exposure and further protect the content from losing its usefulness. Packaging will also protect the chemical products from moisture and contamination, which are the causes of low quality.

Powder packaging machines significantly enhance work efficiency and productivity because they package products without human effort. That way, less time and manpower will be consumed in sorting the products; hence a business will be able to produce more without increasing the quantity of workers. Automation can also handle large volumes faster and more predictably, which is promising to satisfy market demands.

The machines are designed in a way that they are able to package high precision powders in order to secure repeatable quality and exact quantities in every pack. This is very important, particularly in the pharmaceutical industry where the dosage must be the right one. State-of-the-art filling systems ensure that each package contains the exact amount, leading to waste reduction and satisfaction on the customer’s side.

The businesses save a huge amount of money by automating the packaging process, as it reduces the cost of labor and loss by waste. Leakage of the products, contamination, and damage are also minimized, which further leads to savings by ensuring that the product quantity reduces less, while more product is retained for sale. Additionally, the consistency and reliability of automated systems can reduce costs associated with returns and customer complaints.

The type of powder, volume of the packaging need to be considered, and the level of automation required in packaging should also be taken into account. Other considerations are the speed of the machine, accuracy, ease of use, and compatibility with any existing production systems. Check how much flexibility the machine will offer in handling various sizes and the types of materials that will be used for packaging. Maintenance requirements and operational costs are other factors to consider.

Assess your specific needs and requirements to find the best machine for your operation. This will include consideration of the nature of your product (food-grade, pharmaceutical, or industrial), the capacity of production, budget, and space availability. Conducting a thorough needs assessment will help you choose a machine that meets your current needs and can scale with your business growth.

Routine servicing maintains the durability and effectiveness of your machine in packaging powder. Follow the manufacturer’s maintenance schedule regarding the servicing levels of your machine. Ensure you clean it properly once you are done working with it, as well as look at components for any signs of visible wear and tear. Lubricate moving components and replace those worn-out parts in time. It is also good to keep detailed maintenance records for purposes of identification of patterns and preventing potential problems.

Common issues with powder packaging machines include clogging, inaccurate filling, and machine jams. Addressing these issues promptly with proper troubleshooting techniques can prevent prolonged downtime. For instance, regular cleaning and maintenance can prevent clogging, while calibrating the filling system can resolve accuracy issues. Training operators to recognize and address common problems can also improve machine reliability and performance.

Constant technological improvement in the packaging of powder machines continues to enhance the efficiency and functionality of the machines. Innovations like artificial intelligence connectivity and advanced sensor technologies have turned around the industry. Advanced real-time monitoring and control facilities, predictive maintenance, data-driven decision-making, among others, all contribute to increasing the efficiency of operation and product quality.

This is due to the growing emphasis on sustainability, which has now extended to the design and production of most powder packaging machines through the use of biodegrades. In addition, the packaging process itself is designed to be most energy efficient and reduce waste in various processes. Besides, all manufacturers are reducing carbon footprints by applying sustainable practices in their manufacturing processes and materials.

The powder packaging machine industry is growing due to the increasing demand for the machines from multiple industries. The ever-growing importance of packaging food, pharmaceuticals, and advanced packaging technology is likely to be a major driver of market growth. Companies investing in modern and efficient packaging will likely stand in a better position to stay competitive.

Emerging markets present more opportunities for powder packaging machines. This is because with the economy growing in regions like Asia, Africa, and Latin America, the populations are expected to have more need for packaging solutions to meet their growing consumer appetites. There is a growth in such markets in manufacturing and industrial activities, thus providing an increased demand for packaging technologies.

Powder packaging machines are essential for efficient and precise packaging in various industries. One can decide on the type of machine with the knowledge of the different varieties and their unique features and benefits for maximum operations. From manual to fully automatic machines, each type offers its own strengths and weaknesses and is best suited for different scales of production.

A powder packaging machine will go a long way in enhancing productivity, saving costs, and cutting numerous product quality problems. Be informed about the latest trends and advancements to maximize the benefits of these innovative machines. Whether you’re in the food, pharmaceutical, or chemical industry, choosing the right machine can transform your packaging operations and help you stay competitive in the market.

Relevant Recommendation