In the fast-paced packaging industry, the demand for higher productivity, faster processing times, and reduced operational costs has led to the development of advanced packaging technologies. One such innovation is the multi-lane stick packaging machine. Designed to increase output while maintaining accuracy and consistency, multi-lane stick packaging machines are increasingly popular in sectors such as food, pharmaceuticals, and nutraceuticals. These machines are built to efficiently package a wide variety of products, including powders, liquids, and granular materials, into convenient, single-serve stick packs.

A multi-lane stick packaging machine is an advanced piece of equipment designed to simultaneously fill multiple stick packs or sachets in parallel, using multiple lanes (usually between 2 to 12 lanes, depending on the machine). These machines are specifically engineered for high-volume production environments where speed, precision, and efficiency are paramount. By operating multiple lanes at the same time, the machine significantly increases throughput, making it ideal for businesses that need to meet large-scale demand in a shorter time frame.

In a typical operation, the multi-lane stick packaging machine uses several forming tubes, each of which forms and seals a separate stick pack. Each lane can be individually controlled, allowing for flexibility in production and the ability to handle various pack sizes and products simultaneously. The machine can fill and seal products such as powder (e.g., sugar, coffee, spices), liquids (e.g., sauces, honey), and semi-liquids (e.g., ketchup, gel, or liquid condiments).

The core feature of a multi-lane stick packaging machine is its ability to run multiple lanes concurrently. Each lane is fitted with an individual filling system, typically a volumetric filler, to ensure accurate dispensing of the product into each stick pack. Depending on the product, the filling system may include auger fillers for powders, peristaltic pumps for liquids, or piston fillers for thicker products. The simultaneous filling of multiple lanes enhances the machine’s overall throughput, making it well-suited for large-scale production.

Each lane is equipped with a forming mechanism that creates the stick pack. Roll stock film is unwound and fed into the machine, where it is shaped into individual stick pouches. The forming mechanism is responsible for ensuring uniformity in the size and shape of the stick packs, which is crucial for maintaining product consistency and ensuring easy handling and packaging.

Once the product is filled into the stick packs, the machine’s sealing system is used to close each stick pack securely. Heat-sealing technology is commonly used to ensure that the ends of the stick packs are properly sealed, preventing leakage and contamination. The sealing system must be highly precise to avoid any product spillage or quality issues.

After the products have been filled and sealed, the cutting mechanism is responsible for dividing the continuous strip of stick packs into individual pouches. The cutting system uses knives or rotary cutters to make clean cuts between each stick pack. The machine is designed to ensure accurate and smooth cuts to prevent packaging defects that could affect product presentation or functionality.

Multi-lane stick packaging machines have become an essential component in high-speed, high-volume packaging environments. Their ability to fill and seal multiple packs simultaneously makes them invaluable in industries that demand both efficiency and consistency. From food and beverages to pharmaceuticals and cosmetics, multi-lane stick packaging machines offer flexibility, speed, and accuracy, ensuring that manufacturers can meet consumer demand while maintaining product quality. With ongoing advancements in technology, the market for multi-lane stick packaging machines will continue to grow, offering businesses the tools to stay competitive in a rapidly evolving packaging landscape.

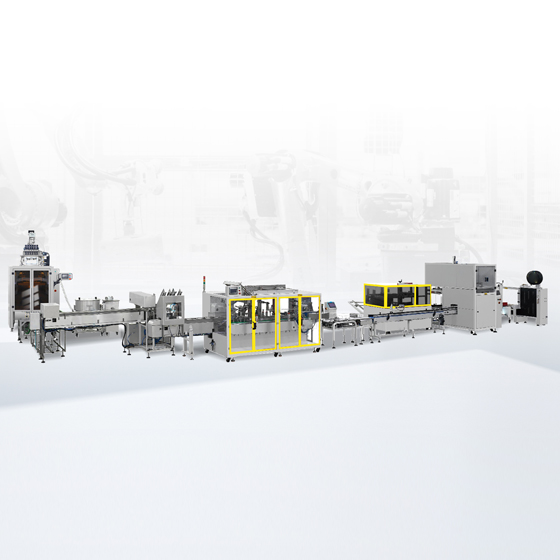

Relevant Recommendation