Automatic Packing Machine: Engineering Efficiency with Ruipuhua

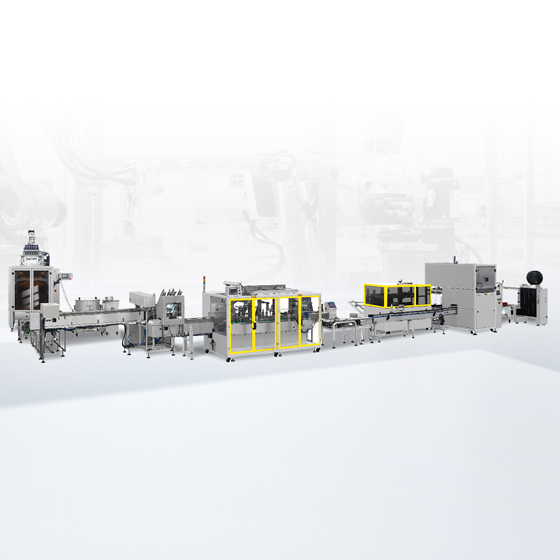

In the modern industrial landscape, speed, consistency, and precision are non-negotiable. As businesses strive to meet escalating consumer demands, optimize labor costs, and ensure flawless product presentation, the transition from manual or semi-automatic processes to full automation has become a strategic imperative. At the heart of this transformation lies the automatic packing machine—a sophisticated symphony of mechanics, control systems, and intelligent design. For companies seeking not just automation, but reliable, adaptable, and efficient automation, the journey often leads to exploring solutions from established innovators. In this realm, the name Ruipuhua resonates as a symbol of robust engineering and tailored performance, offering more than just a machine, but a comprehensive productivity solution.

An automatic packing machine is fundamentally a force multiplier. It replaces repetitive, physically demanding manual tasks with a seamless, continuous operation that runs across shifts without fatigue. This delivers immense and immediate benefits: dramatically increased output rates, unwavering consistency in package quality, and significant reductions in labor costs and physical strain on workers. Furthermore, automation enhances hygiene and safety in sensitive environments like food and pharmaceutical packaging by minimizing human contact with the product. From forming and filling bags to cartoning, case packing, palletizing, and stretch wrapping, automatic systems handle each step with a level of precision that is virtually impossible to maintain manually over a prolonged period.

However, not all automatic packing machines are created equal. The true measure of such an investment lies in its reliability, flexibility, and integration capabilities. A machine that offers high speed but frequently jams or requires constant calibration creates costly downtime. A rigid system that cannot accommodate a slight change in product size or packaging material can become obsolete with the next product line refresh. This is where the engineering philosophy of a brand like Ruipuhua becomes critically important. Ruipuhua approaches automation with a deep understanding of these practical challenges on the factory floor.

Ruipuhua’s range of automatic packing machines is built on a foundation of durability and intuitive design. Their equipment, whether it’s an automatic vertical form-fill-seal (VFFS) machine for powders and granules, a high-speed cartoner for boxes, or a robust case packer, utilizes high-quality components and proven mechanical principles. This focus on robust construction translates directly into higher overall equipment effectiveness (OEE)—less unplanned downtime, lower maintenance costs, and a longer operational lifespan. For a production manager, this means predictable output and peace of mind, ensuring that the automation investment pays dividends every single day.

Beyond reliability, flexibility is a cornerstone of Ruipuhua’s value proposition. Modern markets demand agility. Ruipuhua engineers its machines with smart features that facilitate quick changeovers. Think of servo-driven movements that allow for tool-less adjustments via the human-machine interface (HMI), modular components that can be swapped easily, and wide range of compatible packaging materials. This means a single Ruipuhua automatic packing line can efficiently run multiple product variants, allowing manufacturers to respond swiftly to market trends or seasonal demands without investing in entirely new machinery. This adaptability protects and extends the capital investment over many years.

Another key aspect is intelligent control. Ruipuhua’s automatic systems are typically governed by advanced programmable logic controllers (PLCs) with user-friendly touchscreen interfaces. These systems do more than just run the machine; they provide valuable data and diagnostics. Operators can monitor production counts, track efficiency, and quickly identify fault locations, streamlining troubleshooting. This level of control empowers teams to manage the packaging process proactively, fine-tuning operations for peak performance and ensuring consistent, high-quality output that protects brand integrity.

Choosing the right automatic packing machine partner is a strategic decision. It requires a vendor who understands your specific product, throughput requirements, and future growth plans. Ruipuhua distinguishes itself through a collaborative approach. They work closely with clients to analyze needs and often provide customized solutions, ensuring the machine integrates perfectly into the existing production workflow. Their comprehensive support—from installation and commissioning to operator training and readily available spare parts—ensures a smooth transition to automation and sustained, uninterrupted performance.

Ultimately, investing in an automatic packing machine is about securing a competitive edge. It’s about building capacity, ensuring quality, and controlling costs in a dynamic global market. A Ruipuhua machine embodies this strategic investment. It represents a commitment to engineering excellence, operational resilience, and intelligent design.

For businesses ready to transcend the limitations of manual packaging and embrace a future of streamlined, high-volume, and flawless production, the path forward is clear. The automatic packing machine solutions from Ruipuhua offer more than automation; they offer a reliable, flexible, and smart foundation for industrial growth and enduring success. It is where sophisticated technology meets practical, day-to-day operational excellence on the factory floor.

Relevant Recommendation